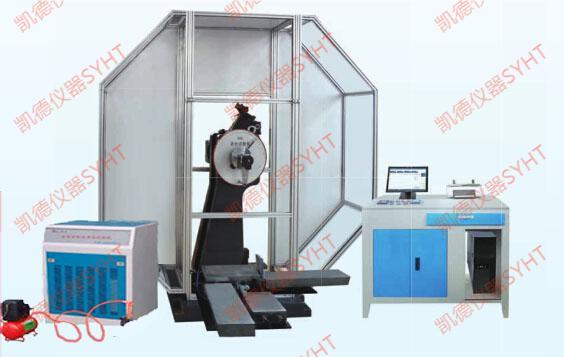

WEW-300D/600D/1000D series microcomputer controlled electro-hydraulic servo universal testing machine

1、 Function and structure

1) WEW-D series microcomputer screen display type hydraulic universal testing machine is mainly done on the mechanical properties of metal materials and non-metallic materials in the tensile, compression, bending and shear test. The mechanical properties of the material such as high strength bolt, chain, wire rope, etc.. The oil cylinder underneath type four column double screw stiffness testing machine host as a platform, the computer measurement and control system is equipped with complete test data automatic measurement, equipment function and increased efficiency in the use of, is professional, high reliability, high degree of integration, flexible and convenient operation, easy upgrade, etc., and with change of the testing machine and the development of standards and constantly enrich and perfect. The machine adopts manual back valve control, hydraulic loading, electronic measurement, microcomputer data processing,.

2) The use of computer to complete the test parameters of the test process, test data and test curve of the collection, processing, analysis, storage and display.

3) This machine is equipped with a computer, printer, electronic extensometer gauges, photoelectric encoder and computer screen display testing machine, special test software, can accurately measure all material or component performance parameters, such as the tensile strength of metal materials, yield strength, non proportional extension strength, elongation, modulus of elasticity and other mechanical properties of provisions. Test results can be reported for six kinds of experimental curves of the test curves and the related experimental tests of the force displacement, force deformation, stress displacement, stress deformation, force time, deformation time.

2、Main specification

|

1 |

Max. capacity(KN) |

300 |

600 |

1000 |

|

2 |

Measuring range |

2%-100% of FN |

||

|

3 |

Relative error of reading |

≤±1% |

||

|

4 |

Displacement measurement Resolving power(mm) |

0.01 |

||

|

5 |

Deformation measurement accuracy |

≤±0.5% |

||

|

6 |

Clamping method |

Hydraulic clamping |

||

|

7 |

Round specimen clamping range(mm) |

Φ6-Φ40 |

Φ6-Φ40 |

Φ6-Φ40 |

|

8 |

Flat specimen clamping range(mm) |

0-30 |

0-30 |

0-30 |

|

9 |

Max. flat specimen clamping width(mm) |

75 |

75 |

75 |

|

10 |

Max. tension test space(mm) |

670 |

670 |

750 |

|

11 |

Max. compression test space(mm) |

430 |

430 |

500 |

|

12 |

Cabinet dimensions(mm) |

1100×700×950 |

||

|

13 |

Load frame dimensions(mm) |

840×720×2000 |

840×720×2000 |

920×820×2200 |

|

14 |

Pump motor power (KW) |

2 |

||

|

15 |

Load frame weight(Kg) |

2600 |

2600 |

3300 |

|

16 |

Column net distance(mm) |

480 |

480 |

580 |

|

17 |

Compression platen size(mm) |

204×204 |

||

|

18 |

Span of bending roller(mm) |

300 |

||

|

19 |

Width of bending roller(mm) |

140 |

||

|

20 |

Shearing specimen diameter(mm) |

Φ10 |

||

|

21 |

Max. piston stroke(mm) |

150 |

||

| 22 |

Host structure |

4 column 2 lead screw | ||