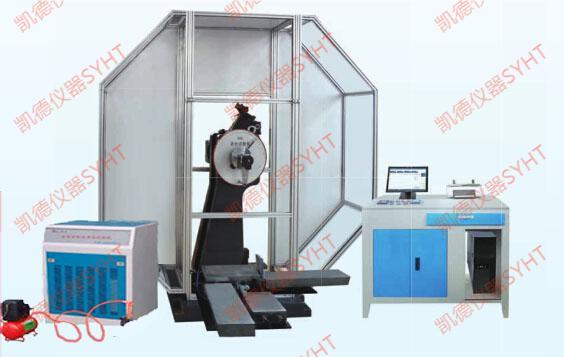

KDJGW-Y60 Automatic Metal Material Bending Tester

I、Overview

1. KDJGW-Y60 automatic metal material bending testing machine is a testing equipmentspecially developed for steel bar and steel pipe bending test. It adopts self-developed servo control system technology, uses motor, precision plunger pump and other valve groups, and is accurately controlled by PLC (programmable controller), and the bending angle can be accurately realized. This machine is an indispensable test equipment for steel mills, steel pipe factories, testing units, quality inspection units, colleges anduniversities to test the bending performance of steel pipes.

2. KDJGW-Y60 automatic metal material bending testing machine meets the following standards:

1) 6.4 in cj136-2007 of plastic lined composite steel pipe for water supply;

2) Straight seam welded steel pipe 6.5.2 and 6.8.1.5 in GB / t13793-2008;

3) Welded steel pipe for low-pressure fluid transportation, GB / T 3091-2001, 5.5.1 provisions on bending test of steel pipe;

4) Comply with the relevant requirements of metal pipe bending test method GB / t244-2020.

5) Comply with the relevant requirements of metal material bending test method GB / t232-2010.

6) Comply with the relevant requirements of steel for reinforced concrete Part 2: hot rolled ribbed reinforcement gb1499.2-2018.

3. Automatic control of any bending angle: digital real-time display of bending angle, touch key operation to realize the automatic bending of 180 º, 90 º, 30 º and 10 º reinforcement or steel pipe specified in national standards (the software has been set and selected by one key cycle), or any angle can be realized by touch key input according to the user's requirements.

4. Loading mode: ordinary motor or servo motor, optional.

II、Main technical indicators:

(1) Applicable parameters of steel pipe bending

1. Maximum bending diameter of steel pipe: 60.3mm

2. Distance between support rollers: adjustable (suitable for steel pipe bending test below 60.3mm)

3. Arc radius of support roller: selected according to the diameter of steel pipe

4. Cylinder stroke: 400mm

5. Bending angle: 10 º 30 º 90 º (different bending centers can be equipped to change the bending angle) or any angle

6. Power supply voltage: 380V 50Hz

7. Overall dimension: 900 × six hundred × 1800mm

8. Weight: 900kg

9. Standard configuration:

1) Host: 1 set

2) Hydraulic control system: 1 set

3) Bent core

a. Standard configuration: 6 times bent core: 1 piece for 21.3 * 6, 26.9 * 6, 33.7 * 6, 42.4 * 6, 48.3 * 6 and 60.3 * 6 respectively, 6 pieces in total;

b. Optional: 8 times bent core: 1 piece each for 21.3 * 8, 26.9 * 8, 33.7 * 8, 42.4 * 8, 48.3 * 8 and 60.3 * 8, 6 pieces in total;

c. Note: bent cores of other specifications can also be customized according to customer requirements.

(2) Applicable parameters of reinforcement bending

1. Diameter range of bending reinforcement: φ 6- φ 40mm

2. Positive bending angle: arbitrarily set within 0-180 °

3. Reverse bending angle: arbitrarily set within 0-23 °

4. Cylinder stroke: 400mm

5. Power supply voltage: 380V or 220V

6. Cold bending indenter: φ 6- φ 220mm optional or specially customized

For more detailed parameters and technical data, please consult the technical or Sales Department of the company.