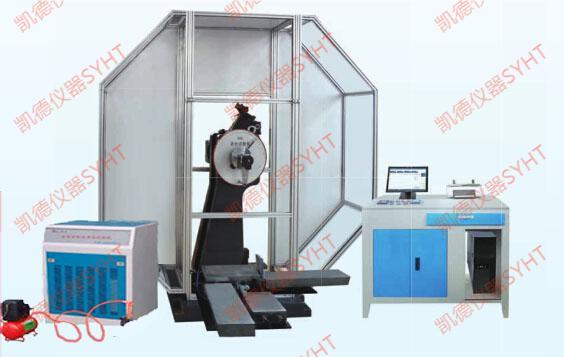

JBWZD-300C Microcomputer Controlled Automatic Low Temperature Pendulum Impact Testing Machine

I、Overview

This machine is an instrument for testing the impact resistance of metal materials under dynamic load. It can continuously do a large number of metal impact tests. It adopts full automatic control. The control system adopts imported programmable controller (PLC) to control the whole process of swing taking and impact test through microcomputer software program. Display impact absorption energy, impact toughness, pendulum rotation angle and print test report, etc. The utility model has the advantages of simple operation, safety, reliability and high work efficiency. The machine is equipped with protective net cover, which provides conditions for users' safe operation. It is not only a necessary testing instrument for metal material manufacturers and quality inspection departments, but also an indispensable testing instrument for new material research in scientific research institutions.

II、Executive standard:

1. GB / t3808-2002 inspection of pendulum impact testing machines

2. Metallic materials Charpy pendulum impact test method (GB / t229-2007)

3. Jjg145-2007 pendulum impact testing machine

4. ASTME23-07a《StandardTestMethodsforNotchedBarImpactTestingofPage 1 of 41 of 4 MetallicMaterials》

5. 5 Bsen10045-1:1990 Charpy impact test for metallic materials V-notch and u-notch test methods

6. BS EN ISO 148-1-2010 Metallic materials. Charpy pendulum impact test. Test metho.

III、Main technical parameters:

1. Impact energy: 300j

2. Pre lifting angle of pendulum: 150 °

3. Angle. Small resolution: 0.1 °

4. Distance from pendulum center to impact point (sample center): 750 mm

5. Impact speed: 5.24m/s

6. Span of sample support: 40mm

7. Arc radius at the end of sample support: 1 ~ 1.5mm

8. Inclination of bearing surface of sample support: 11 °± 1 °

9. Arc radius of impact knife: 2 ~ 2.5mm

10. Included angle of impact knife: 30 °± 1 °

11. Thickness of impact knife: 16mm

12. Sample specification (length) × wide × Height): 55mm × 10㎜ × 10(7.5、5、2.5)㎜

13. Ambient temperature: 10 ~ 35 ℃ (it is required to install at least household air conditioner)

14. Overall dimension of main engine (L) × wide × Height): About 2100mm × 835㎜ × 2100㎜

15. Host weight: about 900kg

16. Host power supply: AC three-phase five wire 380V ± 10% 50hz1.5kw

17. Environmental conditions: there is no corrosive medium, vibration and strong electromagnetic field interference in the surrounding environment.

Note: the user is responsible for the construction of equipment foundation.

Optional: totally enclosed protective net