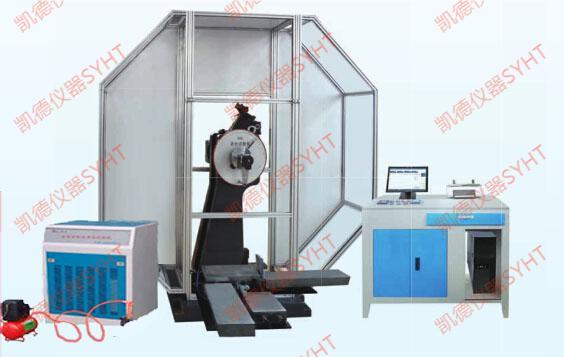

GWY-40 / 50 / 60 Steel Bending Tester

I、Overview of steel bending testing machine:

1. GWY series steel bending testing machine is used for bending experiments of round steel, bar, plate, construction deformed steel and steel pipe. It can carry out forward bending and reverse bending tests to determine its bending plastic bending capacity. It is a multifunctional steel bending testing machine. The maximum size of bending specimen is optional: φ 40mm、 φ 50mm、 φ 60mm.

2. The single piston rod double acting hydraulic cylinder is used for loading, and the front end of the working piston is equipped with a plug-in cold-formed pressing roller seat, which makes it very convenient to replace the cold-formed pressing head. It can be widely used in building materials, metallurgy, scientific research institutions, colleges and universities, quality inspection centers and commodity inspection departments. It is an ideal bending testing machine required by industries such as production, scientific research and teaching.

3. The machine meets the latest standards GB / t1499.2-2018 steel for reinforced concrete Part 2: hot rolled ribbed steel bars, Yb / T 4828-2020 hot rolled ribbed steel bars for reinforced concrete, Yb / T 4657-2018 four sided ribbed steel bars for reinforced concrete, GB / T 244-2020 test method for bending of metal pipes, Yb / T 4362-2014 stainless steel bars for reinforced concrete and GB / T 232-2010 Test requirements of bending test method for metallic materials.

II、Main technical indexes of steel bending tester:

Serial number model GWY-40/50/60

1. Maximum thrust 300kN

2. Working stroke 400mm (optional 500mm)

3. Maximum working pressure 31.5MPa

4. Bending center diameter φ 6- φ 200 (general configuration, special customization for other specifications)

5. Diameter of round (flat) specimen φ 6- φ 40(6-40)mm

6. power 4kW

7. Overall dimension one thousand three hundred and ten × seven hundred and ninety × one thousand and eighty-five

8. Positive bending angle 180°90°

9. Reverse bending angle 20°

10. Bent core specification 1 set of random bending core (bending core of other specifications can also be customized)

For more detailed parameters and technical data, please consult the technical or Sales Department of the company