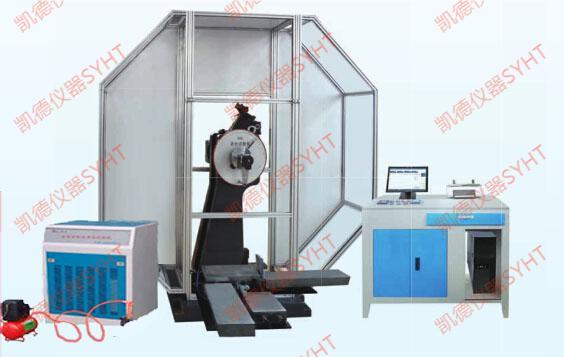

MM-U5G Microcomputer Screen Display Material End Face High Temperature Friction And Wear Tester

I、Overview

The microcomputer screen display material end face high temperature friction and wear tester adopts the form of sliding friction and is used to evaluate the friction and wear properties of metals, engineering composites, powder metallurgy, alloy bearings and other materials under specified test conditions. The test can be carried out at room temperature - 800 ℃ under various conditions of oil-free lubrication, oil immersion lubrication and changing parameters such as load, speed, friction mate material, surface roughness and hardness. The friction temperature rise and friction coefficient of the material can be measured. This machine is suitable for measuring and analyzing the friction and wear properties of materials.

II、Main technical parameters

1. Maximum test force (KN): 5

2. When the maximum test force is more than 20%, the test force accuracy: ≤± 1%;

3. Maximum measured friction (n): 500

4. Above 20% of the maximum friction, friction accuracy: ≤± 2%

5. Spindle speed range (R / min): 100

6. Spindle speed error (R / min): ± 10

7. Spindle control of testing machine: manual control, time control, speed (cycle) control, friction control

8. Time display and control range of testing machine: 1s-9999s (min)

9. Display and control range of test machine revolution (cycle): 1-999999

10. Measuring temperature range of testing machine: room temperature ~ 800 ℃

11. Overall dimension of testing machine (length) × wide × Height (mm): about 1200 × eight hundred and ten × one thousand and seven hundred

12. Mass of testing machine (kg): about 800

For more detailed parameters and technical data, please consult the technical or Sales Department of the company.