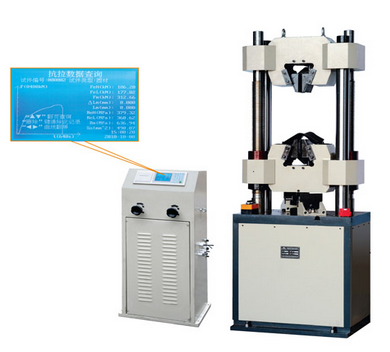

WE-100B/300B/600B/1000B series microcomputer controlled electro-hydraulic servo universal testing machine

1、 Function and structure

WE-B series electro hydraulic universal testing machine (liquid crystal digital display) is mainly used in the tensile, compression, bending and shear test of various metal materials. It can also be used for the compression test of non metallic materials such as plastic, concrete, cement, etc.. The experimental data are easy to be directly measured by the electronic measuring force, the time curve, the test force, the peak value of the test force, the yield strength of the material, the mechanical properties of the material, the tensile strength and the tensile strength of the materials. This machine adopts the oil cylinder under the condition of low, high, easy to operate, is the industrial and mining enterprises, scientific research units, universities, engineering quality supervision station and other departments of the ideal test equipment.

2、Main specification

|

No. |

Item |

Specification |

Specification |

Specification |

Specification |

|

|

1 |

Max. capacity(KN) |

100 |

300 |

600 |

1000 |

|

|

2 |

Measuring range |

4%-100% of FN |

||||

|

3 |

Relative error of reading |

≤±1% |

||||

|

4 |

Test force resolution (kN) |

0.01 |

||||

|

5 |

Clamping method |

Manual clamping |

Hydraulic clamping |

|||

|

6 |

Round specimen clamping range(mm) |

Φ6-Φ26 |

Φ6-Φ26 |

Φ13-Φ40 |

Φ13-Φ40 |

|

|

7 |

Flat specimen clamping range(mm) |

0-15 |

||||

|

8 |

Max. flat specimen clamping width(mm) |

70 |

70 |

75 |

75 |

|

|

9 |

Max. tension test space(mm) |

550 |

550 |

650 |

700 |

|

|

10 |

Max. compression test space(mm) |

380 |

||||

|

11 |

Cabinet dimensions(mm) |

500×750×1200 |

||||

|

12 |

Load frame dimensions(mm) |

720×580×1950 |

720×580×1950 |

720×580×2100 |

890×660×2200 |

|

|

13 |

Display mode |

LCD digital display, test force - time curve, test force, peak test force |

||||

|

14 |

Pump motor power (KW) |

1.85 |

||||

|

15 |

Load frame weight(Kg) |

1900 |

1900 |

2100 |

2600 |

|

|

16 |

Column net distance(mm) |

520 |

520 |

650 |

740 |

|

|

17 |

Compression platen size(mm) |

204×204 |

||||

|

18 |

Span of bending roller(mm) |

450 |

||||

|

19 |

Width of bending roller(mm) |

120 |

||||

|

20 |

Shearing specimen diameter(mm) |

Φ10 |

||||

|

21 |

Max. piston stroke(mm) |

150 |

||||

|

22 |

Host structure |

2 column 2 wire rod |

||||