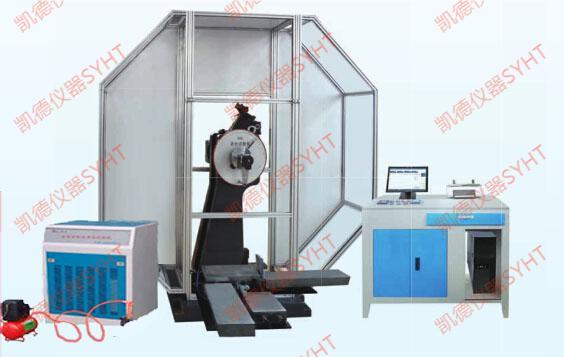

NDW - 500 Microcomputer controlled torsion test machine

One product overview

1, NDW series microcomputer control torsion testing machine by the loading system, transmission system, detection system and computer measurement control system, suitable for metal materials, non metallic materials and metal non metal parts, static torsion mechanical performance test, torque and ultimate torque, the torsional strength of the material can be measured, upper yield point Tau Su, yield point tau SL, torsional angle and torsional shear modulus, shear strain and other technical indicators, and the curve of torque torsion angle, torque, torsional angle time test.

2, the use of horizontal structure, computer software control, screen display, the full digital data acquisition and control system, precision test system, planetary gear reducer drive, with uniform, stable, no impact phenomenon, data acquisition and control accuracy.

3 test function:

WindowsXP, Windows7 Chinese operation platform, to achieve torque, torsional angle, torsional deformation of a variety of control. Using a window type operating system with a graphical interface, the display screen and the operation panel can be set up, the test speed and the control parameters can be set up, and the basic test results can be displayed in real time. Whole digital AC servo control system, digital data acquisition and processing system, photoelectric encoder, the sample of the torsion angle.

Two, applicable standards:

1 JB/T9370 - 2007 "technical conditions for torsion testing machines"

2 GB10128 - 2007 "room temperature reverse test method for metallic materials"

3 JB/T9370 "technical conditions for torsion test machine"

4 JJG269-2006 "verification regulation of torsion test machine"

5 users can also provide the relevant technical standards, in accordance with the standards provided by the user to achieve the test mode control and related data acquisition and processing.

Three, product description

1. The main machine: the horizontal structure, composed of a transmission box, a chuck seat, a machine body, a controller, a computer and software, gear box in the left side of the host, AC servo motor and reducer, chuck a high-accuracy two-way torque sensor, can along the guide rail on the left and right moving; frame structure is adopted in the main structure, to ensure that the whole of rigid. Sample of the installation, disassembly, convenient, fast.

2. The guide rail: activities of the chuck end with a precision linear guide and adjust the operating space, with high rigidity and high accuracy, precision grade precision; guide rated carrying high ability, the allowable vertical load, to withstand the high torque, high anti overload capacity; guide dustproof and self lubrication system is more reasonable;

3 measurement and control technology: the measurement and control system of all digital measurement controller using the most advanced technology. DSP (digital signal processing) technology based on FPGA (high density field programmable gate array). It is characterized by high speed processing ability, ultra low noise, high anti jamming. Automatic zero adjustment, automatic calibration and other functions. With overload, over stroke, over voltage, over current, over heat, etc..

4 drive system: the use of AC servo motor and AC servo driver, speed adjustment range, loading uniform, stable, high precision servo control, long service life.

5 transmission system: the use of imported Swiss equipment production of planetary gear reducer transmission, ensure that the transmission of uniform, stable and transmission accuracy, the horizontal space range of arbitrary manual adjustment.

6 computer system and software package: strict accordance with the relevant standards of the test data to calculate the exact statistics, and equipped with a sound data query function, print function, export function to ensure the accuracy of the test data, reliability, real and reflect the nature and characteristics of the material itself. Modular test management software of each function is an independent module, such as the calculation of the base and the control of test hangar, etc. are independent modules, to upgrade or change only alone on its own can be modified without the need to change the whole system.

Four, the main technical performance indicators

1 maximum torque: 500N.m;

2 torque precision measuring range: 0.4% ~ 100%F.S (maximum torque)

3 the relative error of the value of the torque is shown in the value of less than 1% of the accuracy.

4 torque resolution: the maximum torque of 1/ + 300000, the whole process is not divided into file, and maintain the same resolution

5 torsion angle measuring range: no limit

6 the relative error of the torsion angle is shown: the accuracy of the indication is within 1%.

The moving distance between 7 (distance two between the collet chuck): 0 ~ 600mm continuously adjustable

8 reverse speed: 0.36 ~ 720 /min arbitrary setting, stepless speed regulation

9 the relative error of the reverse speed: the setting value of 1% or less

10 coaxial: diameter within 0.2mm

11 power supply voltage: 50Hz AC220V main motor power: 1kW

12 dimensions: 1650*420*1100mm

13 reverse direction: forward to reverse