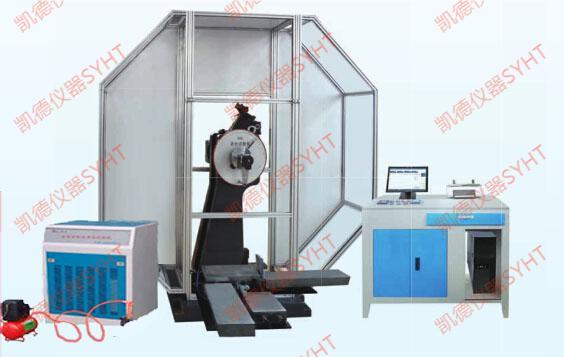

WAW-300E/600E/1000E/2000E series microcomputer controlled electro-hydraulic servo universal testing machine

1、Function and structure

1) WAW-E computer controlled servo hydraulic universal testing machine is designed and produced conform to GB/228-2010, mainly used to execute the tension, compression, bending, shearing etc. test for metal material. Attached simple accessories and devices, it can be used to test wood, concrete. Cement, rubber and so on.

2) The oil cylinder is at the bottom of the load frame, tension space is at the upside of the load frame, compression and bending space is between lower crosshead and working table. The lower crosshead is driven by motor though decelerator, chain transmission device, and screw pair to realize the adjustment of the testing space.

3) The machine adopts oil pressure transducer to measure load, and use ourselves developed computer screen display system. The system can display the load, load peak value, deformation, testing curves. Easily print diverse testing report and as well as edit customized report form by users themselves.

4) Test of space and long experimental stroke the host structure, mounting specimens of various sizes, various fixture, test device and extensometer. So it has strong adaptability.

2、Main specification

No.

Item

Specification

Specification

Specification

Specification

1

Max. capacity(KN)

300

600

1000

2000

2

Measuring range

2%-100% of FN

3

Relative error of reading

≤±1%

4

Displacement measurement

Resolving power(mm)

0.01

5

Deformation measurement

accuracy

≤±0.5%

6

Deformation rate control

precision

The setting value of the rate <0.05%FS is ±2%.

The rate is not less than 0.05%FS ±0.5% value set

7

Constant, constant deformation

constant displacement control precision

Set the value of <10%FS, set the value of less than±1%

The set value is not less than 10%FS, within the set value of±0.5%

8

Clamping method

Build in type hydraulic clamping

9

Round specimen clamping

range(mm)

Φ6-Φ26

Φ13-Φ40

Φ13-Φ60

Φ15-Φ70

10

Flat specimen clamping

range(mm)

0-15

0-30

0-40

0-60

11

Max. flat specimen clamping

width(mm)

70

80

120

100

12

Max. tension test space(mm)

800

800

850

800

13

Max. compression test space(mm)

700

700

700

700

14

Cabinet dimensions(mm)

1100×700×950

15

Load frame dimensions(mm)

990×600×2435

990×600×2453

1100×770×2490

1160×1100×2600

17

Pump motor power (KW)

2.3

3.4

18

Load frame weight(Kg)

2800

3000

4500

6500

19

Column net distance(mm)

520

520

650

740

20

Compression platen size(mm)

204×204

21

Span of bending roller(mm)

450

22

Width of bending roller(mm)

140

23

Shearing specimen diameter(mm)

Φ10

24

Max. piston stroke(mm)

250