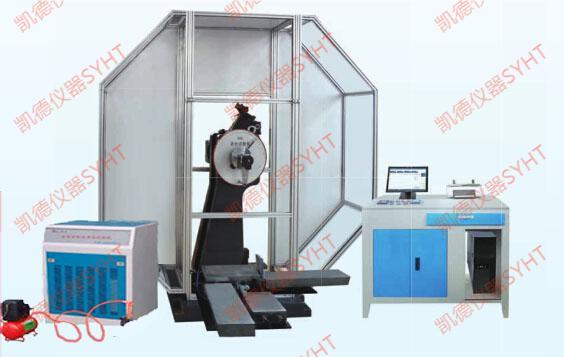

MR-S10 Series Four Ball Friction Testing Machine

I、Product introduction

1. MR-S10 series four ball friction testing machine is mainly used to evaluate the bearing capacity of lubricants in the form of sliding friction under extremely high point contact pressure. It includes three indexes: maximum non seizure load Pb, sintering load Pd and comprehensive wear value zmz. In practical application, different evaluation indexes can be selected according to various uses of lubricants.

2. The four ball friction testing machine is strictly produced in accordance with JB / T 9395-2004 technical conditions for four ball wear testing machine. It adopts computer full digital control mode. It can do long-term wear resistance test of lubricant, measure friction coefficient and record friction and temperature curve.

3. Applicable standards of this machine:

1) GB/T12583-98 Determination of extreme pressure properties of lubricants (four ball machine method)

2) GB3142-82 Test method for bearing capacity of lubricants (four ball method)

3) SH/T0189-92 Determination of antiwear properties of lubricating oils (four ball machine method)

4) SH/T0202-92 Determination of extreme pressure properties of lubricating greases (four ball machine method)

5) SH/T0204-92 Determination of antiwear properties of lubricating greases (four ball machine method)

II、Main technical parameters

1. Maximum test force (KN): 10

2. Measurement range of test force: 0.06% ~ 20% of the maximum test force; 20%~100%

3. Relative error of test force indication; ± 1%, below 400N ± 5N

4. Automatically maintain the indication error when the test force is long; ± 1% FN (per stage)

5. Measurement range of two gears of friction (n); 0~50; 0~300

6. Single stage continuously variable transmission system (R / min); 200~2000

7. Spindle speed error (R / min); ±10

8. Friction load sensor (n); fifty

9. Oil box stroke (mm) > forty-five

10. Taper of spindle inner hole; 1:7

11. Working range of heater temperature: room temperature ~ 250 ℃

12. Temperature control range: ≤ 2 ℃

13. Diameter of special standard steel ball (mm): φ twelve point seven

14. Spindle motor power (kw): 2.2

15. Spindle control of testing machine: manual control, time control, speed (cycle) control, friction control

16. Time display and control range of testing machine: 1s-9999s (min)

17. Display and control range of revolution (cycle) of testing machine: 1-999999

18. Overall dimension of testing machine (length) × wide × Height (mm): about 1200 × eight hundred and ten × one thousand and seven hundred

19. Mass of testing machine (kg): about 850

For more detailed parameters and technical data, please consult the technical or Sales Department of the company.