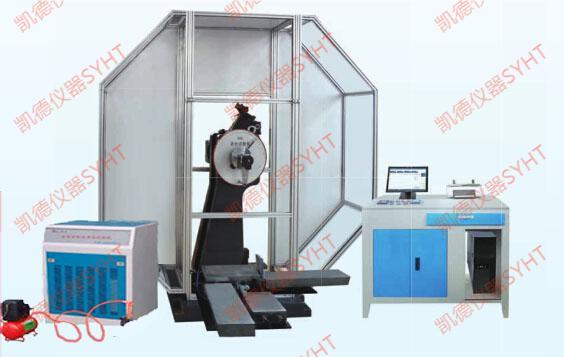

NJX-10 Metal Wire Torsion Testing Machine

I. the wire torsion testing machine use:

NJX series wire torsion testing machine is mainly used to determine the diameter φ0.3-φ1mm, φ1-φ3mm, φ3-φ10mm metal wire to withstand plastic deformation ability in one or both directions in reverse, the testing process can display wire surface defects . Suitable for scientific research departments, universities and industrial and mining enterprises Mechanics Laboratory performance measurement used to reverse the material, particularly suitable for the manufacture of wire incoming inspection units and the use of wire-line detection units.

II. the wire torsion testing machine Features:

1. torsion testing machine has two or three rotational speeds to choose from, such as 30,60,90,120,180,300 rev / min, via a belt pulley adjustment;

2. can clamp wire length 300-100mm, 500-300mm; guide pulley weight plus the axial force, the liquid crystal display after the test laps, breaking test specimen ring value is automatically latched.

3. Applicable standards

1) GB / T239.1-2012 "The first part of the metal material wire unidirectional torsion test method"

2) GB / T239.2-2012 "the second part of metallic material wire bidirectional torsion test method"

III. the wire torsion testing machine main technical parameters:

1. Model: NJX-1, NJX-3, NJX-5,NJX-10,NJX-20,NJX-30

2. The range can clamp the metal wire diameter (mm): 0.3-1; 1-3; 3-10

3. Move the parallelism of the entire length of the rail (mm): <0.2

4. The maximum distance between the grips (mm): 100-300; 100-300; 300-500

5. The rotational speed (rev / min): 60,180,300; 60,90,120; 30,60,90

6. The speed error: <± 10%

7. jaws Hardness (HRC): 55 ~ 65

8. Weight Tolerance: ± 0.5%

9. The test machine operating noise (dB): <75

10. The operating voltage (V): AC 380V ± 0% 50Hz